Introduction

Following your request, our specialists will connect with you to evaluate your setup, clarify ROI potential, and guide you through the next steps.

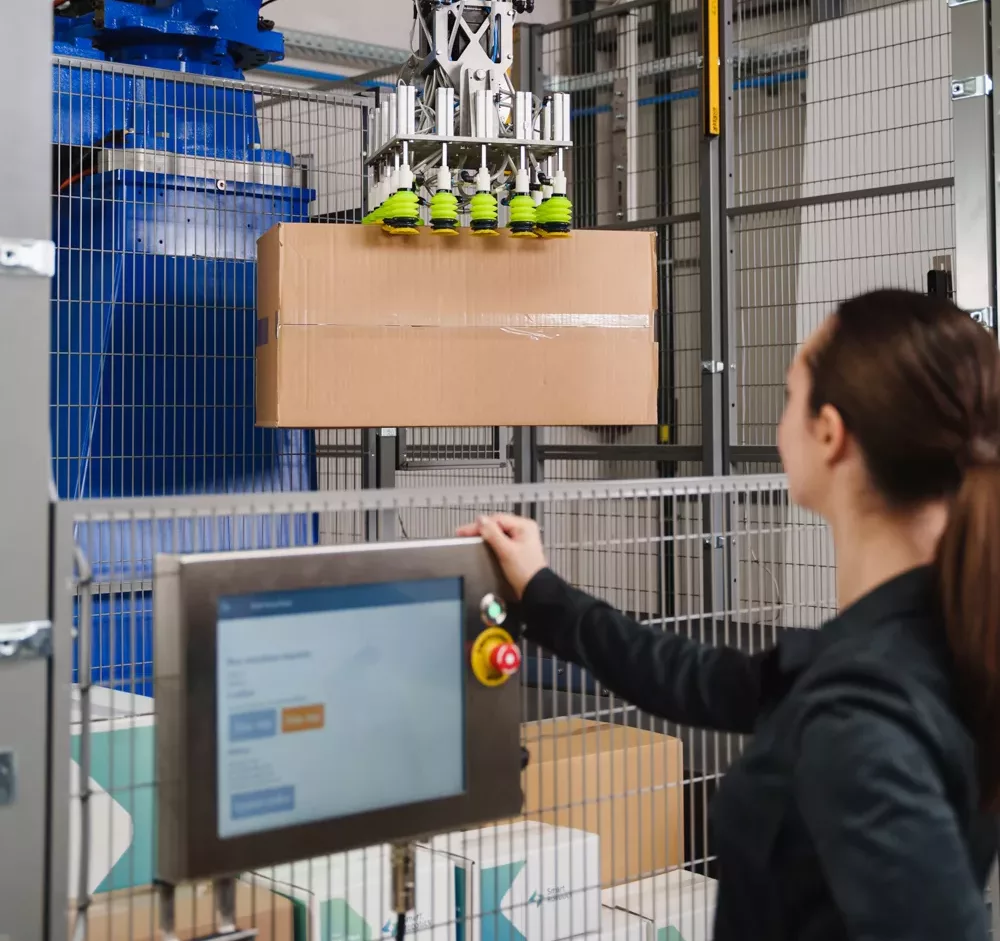

Keep your end-of-line palletizing flowing, even when labor is hard to find. Choose between our Cobot Palletizer for single-SKU lines and our Mixed Case Palletizer for mixed case robotic palletizing.

This AI-driven, compact robot palletizing system stacks single SKUs onto pallets at the end of a production line.

Powered by AI, this robotic palletizer efficiently handles mixed-case SKUs and heavy loads, stacking them neatly onto pallets.

The benefits of palletizing solutions include increased efficiency, improved health and safety and reduced labor costs. Palletizing solutions can be customized to meet the specific needs of a business.

Finding people for repetitive, physically demanding work is a challenge. A robot palletizing system takes that pressure off your operations, day after day.

A robot palletizing system knows exactly what to stack, where, and in which order – so you don’t have to worry about mishandling or damage.

With palletizing automated, your team can shift into higher-value roles – reducing turnover and boosting morale across your operations.

When palletizing runs consistently, you rely less on external labor and achieve a return on investment in no time – typically seen within 6 months to 2 years.

Boxes

Open boxes

Crates

Wraps

Following your request, our specialists will connect with you to evaluate your setup, clarify ROI potential, and guide you through the next steps.

After aligning on your needs, we’ll develop and test a customized solution to ensure it’s fully ready for setup at your facility.

Next, we install and test the system on-site and train your team on product updates and troubleshooting, so adjustments are fast and easy.

From day one and well into the future, we’re here to keep your operations running smoothly. Our service team is just a call or message away, with secure remote access for quick issue resolution.

“It is no surprise I would recommend Smart Robotics to our partners”

“With our extensive range of products, a picking application must know really well what products it picks and how to place them correctly”

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

“We immediately got the impression that Smart Robotics is a solid and reliable company.”

“Best installation of any machinery in our facility.”

“The user-friendliness of the system played a large role in the decision making process.”

Automation can transform your operation, but only if you understand the full picture of long-term costs and savings. This article breaks down everything you need to know to make a confident, calculated investment.

“It is no surprise I would recommend Smart Robotics to our partners”

“With our extensive range of products, a picking application must know really well what products it picks and how to place them correctly”

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

“We immediately got the impression that Smart Robotics is a solid and reliable company.”

“Best installation of any machinery in our facility.”

“The user-friendliness of the system played a large role in the decision making process.”

We can help you understand what is possible and how our solutions can best fit your needs.

Fill out the form and check your inbox for:

Looking for more information, or would you like personalized advice?

You can schedule a call with our palletizing experts directly via the link in the email.

A cobot palletizer or robotic palletizer is a cobot system that stacks goods and products onto a pallet. What are the benefits of a cobot palletizer? And where can they be used?

Read more

Global labor shortages continue to rise, also in the food (processing) industry. Automation is key, but where to start? End-of-line automation with cobots or robots can be the perfect first step. This blog gives 5 reasons why end-of-line automation is key.

Read more

The coffee industry is growing and in need of automation to improve efficiency. Palletizing is an easy task to automate with a cobot.

Read more

In 2025, consumers continue to demand more and more from the bakery industry. It is time to consider how to improve the production process to meet these demands. Learn about the latest bakery trends and why bakery automation is key.

Read more