Introduction

Following your request, our specialists will connect with you to evaluate your setup, clarify ROI potential, and guide you through the next steps.

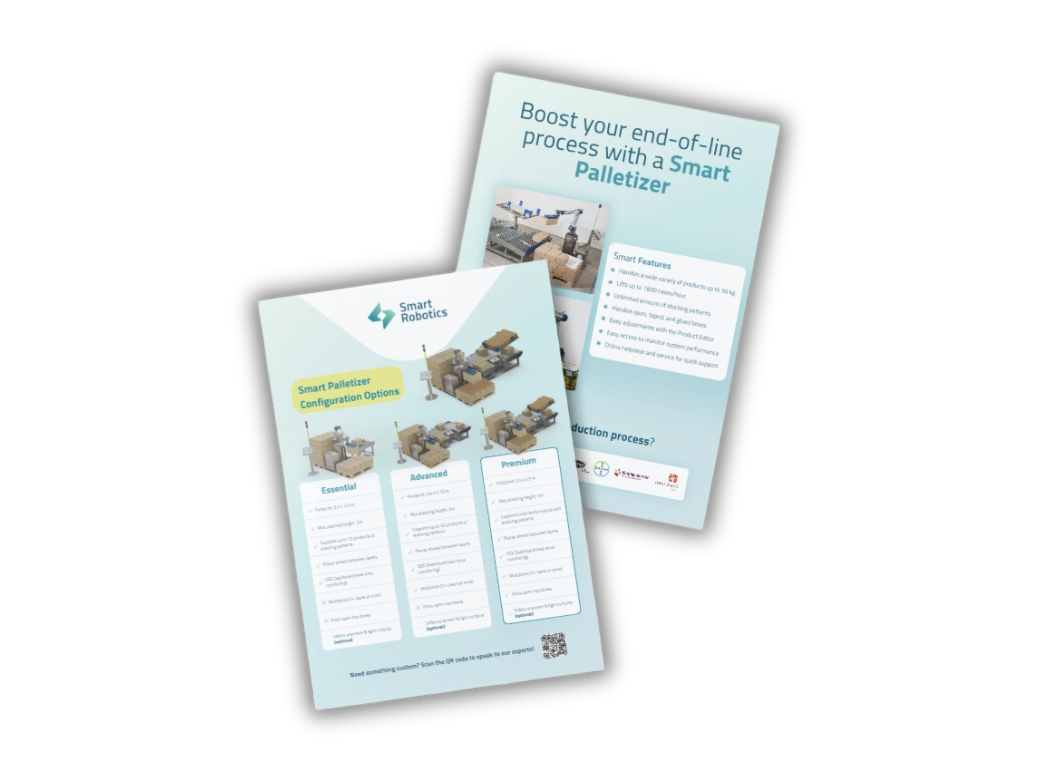

Compare the features of our Smart Essential, Advanced, and Premium configurations for cobot palletizing. This guide will help you identify the right fit based on your unique operational complexity and flexibility needs.

Footprint (L x W)

Max stacking height

Max number of products or stacking patterns

Places sheets between layers

OEE Dashboard (real-time monitoring)

Installed in half a day

Multi-picks (2+ cases at once)

Picks open-top boxes

Best for

Extended flexibility

2.4 x 2.75 m

3m

20

Higher throughput operations with a wider range of products

Request info

Full palletizing capabilities

2.4 x 3.5 m

3m

unlimited

High-volume, multi-SKU operations needing open-box handling—now or in the future

Request infoFootprint (L x W)

2.4 x 2.3 m

Max stacking height

3m

Max number of products or stacking patterns

10

Multi-picks (2+ cases at once)

Picks open-top boxes

Best for

Simple operations with only a few products

Footprint (L x W)

2.4 x 2.75 m

Max stacking height

3m

Max number of products or stacking patterns

20

Picks open-top boxes

Best for

Higher throughput operations with a wider range of products

Footprint (L x W)

2.4 x 3.5 m

Max stacking height

3m

Max number of products or stacking patterns

unlimited

Best for

High-volume, multi-SKU operations needing open-box handling—now or in the future

We’ve been listening to and partnering with our customers since 2015.

Whether it’s crates, taped boxes, or uniquely shaped packaging, we build palletizing solutions to fit their unique production needs. On top of that, we make it incredibly easy to use – that’s why over 100 customers trust us to automate their end of line palletizing process. See how it compares to other palletizing systems in the market:

Advanced Al-Powered Solution

Easy to operate, makes shift handovers simple

Remote & on-site support after installation

Small footprint palletizer, costs less per m²

Easily add or adjust products yourself

Lifts any box type — open or closed

Durable stainless-steel design

Quick, tool-free gripper swaps

Unlimited stacking patterns

Install & go in half a day

ROl in 1-2 years

Traditional Solutions

Difficult to operate, causes downtime between shifts

Install and leave, no aftercare

High cost per footprint

Adding products requires professional help

Struggles with open or unusual box types

Not suitable for food-grade environments

Gripper swaps require time and tools

Limited stacking patterns

Installation takes several days

ROI in over 2 years

Boxes

Open boxes

Crates

Wraps

We’ll help you understand the possibilities and find the cobot palletizer configuration that best meets your needs.

Fill out the form and check your inbox for:

Herman Bliek | Automation specialist

Discover how our customers have improved their production and fulfillment processes with a reliable and efficient palletizing system.

Vandemoortele, a leading food production company, is significantly saving costs after having implemented a Smart Palletizer.

Read more >24/7

Operation

99.7%

Availability Rate

<1

Year ROI

World-renowned Bayer, a pharmaceuticals and life sciences company, has welcomed the Smart Palletizer as a new colleague. Read more about why they recommend Smart Robotics to their partners.

Read more >Safe

palletizing system

Short

delivery times

Packservice, a large co-packing group, implemented a Smart Palletizer to help solve their labor shortage and improve employee health

Read more >Heinerle-Berggold Shokoladen GmbH, a German company specializing in specialty quality chocolates, has implemented a Smart Palletizer to help tackle labor shortages and to ensure on-time delivery to their customers.

Read more >3

Shift Operation

99.7%

Availability

24/7

Operation

Improve ergonomic circumstances of human employees

99.7%

Availability Rate

Stacking closed and open boxes without problem

<1

Year ROI

Saving 1 operator per shift

Safe

palletizing system

One of the most popular colleagues

Short

delivery times

No need to interrupt production

3

Shift Operation

24/7 reliability and efficiency

99.7%

Availability

Reliable palletizing of chocolates

Get our Cobot Palletizer Guide and uncover:

Following your request, our specialists will connect with you to evaluate your setup, clarify ROI potential, and guide you through the next steps.

After aligning on your needs, we’ll develop and test a customized solution to ensure it’s fully ready for setup at your facility.

Next, we install and test the system on-site and train your team on product updates and troubleshooting, so adjustments are fast and easy.

From day one and well into the future, we’re here to keep your operations running smoothly. Our service team is just a call or message away, with secure remote access for quick issue resolution.

Simply put, a cobot palletizer is a compact, easy-to-install, and user-friendly alternative to traditional industrial robots. It automates the stacking of goods onto pallets, and in some cases, into cages or onto trolleys, helping streamline end-of-line packaging processes.

Unlike traditional palletizers, cobot palletizers can safely work alongside employees without the need for fencing. They are an ideal first step for logistics and production facilities looking to automate repetitive tasks and increase efficiency.

A cobot palletizer from Smart Robotics comes as a complete package, including hardware, software, on-site commissioning, and long-term service that continues well beyond installation. Our systems can handle both closed and open boxes using our unique fork gripper. You can easily set up any stacking pattern and adjust product dimensions on the fly. Easy, simple, and straightforward.

Read more about cobot palletizers >Unlike traditional industrial or gantry palletizers, cobot palletizers have a compact footprint and can be easily integrated into existing production lines without hassle.

Smart Robotics’ cobot palletizer is quick to install, simple to operate, and safe to work alongside, thanks to its built-in sensors and intuitive software. By taking over repetitive and heavy lifting tasks, it improves workplace ergonomics while maintaining consistent, high-quality stacking.

Our cobot palletizers also offer a strong return on investment (typically between 6 months and 2 years) through reduced labor costs and minimal downtime. This makes them an ideal choice for businesses looking to scale production efficiently and future-proof their operations.

Read more about cobot palletizers >At Smart Robotics, we make sure you get a cobot palletizer that’s easy to use, flexible when your products or packaging change, and built to last. Installation usually takes less than half a day, and you can start palletizing within minutes.

If you ever need support, our dedicated service team is just a call away. Most issues can be solved quickly through our remote helpdesk, and if needed, we’ll visit your site to get everything running smoothly again.

Most of our customers see a return on investment within 6 months to 2 years, making the Smart Robotics cobot palletizer one of the fastest and most reliable automation solutions available.

Read more about cobot palletizers >A cobot, or collaborative robot, is a type of robot that can safely work together with both people and other cobots. Compared to the traditional industrial robots, they are more affordable, smaller, can easily be deployed in various processes and are built and programmed to co-operate with people. Hence the name ‘collaborative robot’.

Read more about cobot palletizers >We use different suppliers to build your complete palletizing system. We offer a range of robotic arms from our partners tailored to your specifications, they include: Universal Robots – UR10e, UR20 & UR30 and Doosan Robotics.

What hardware comes with the system?

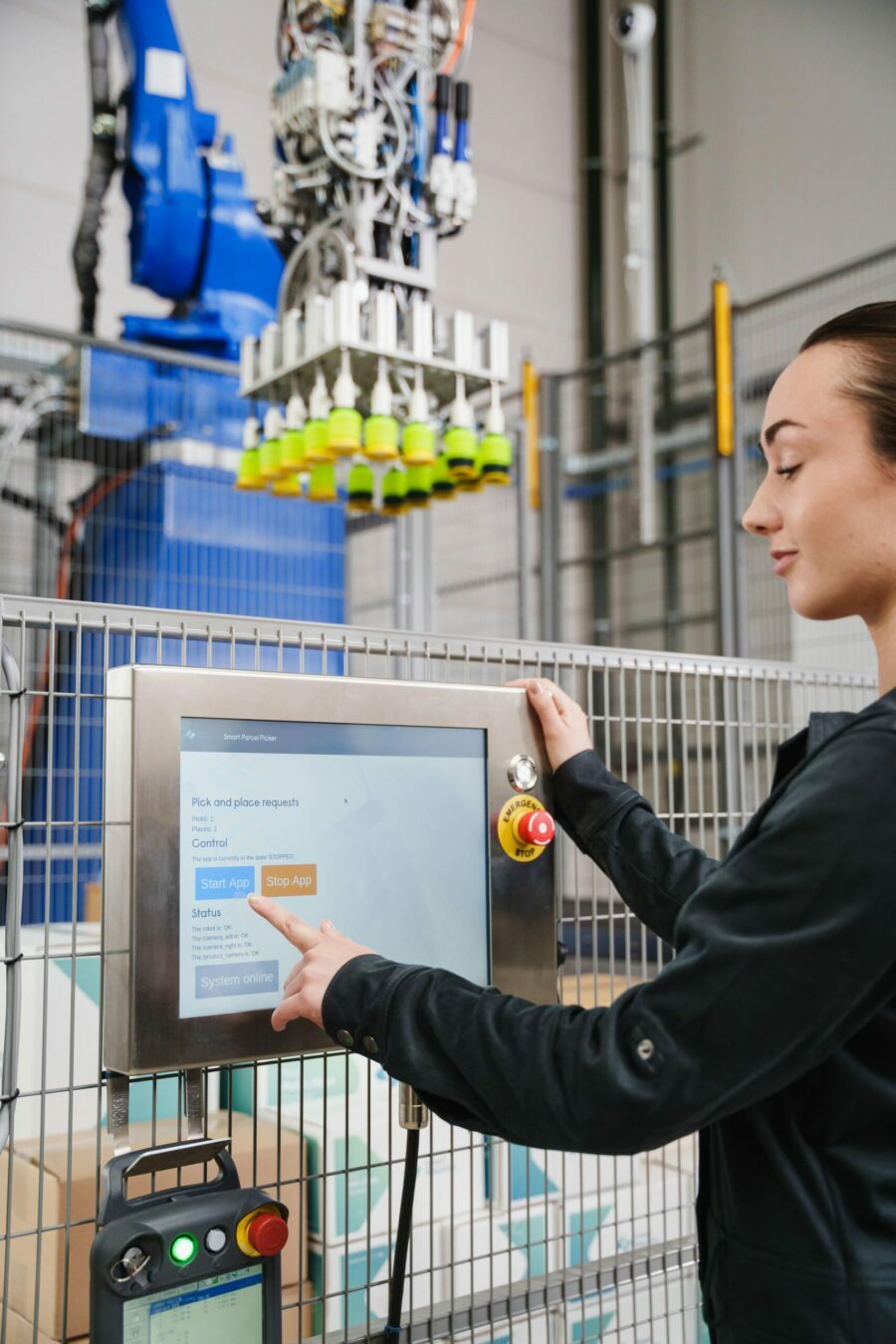

Aside from the robotic arm, we also provide a palletizer frame, vertical lift optional, different gripper options available (vacuum, fork, clamp gripper or custom designed gripper), box supply unit, interlayer sheet optional, additional safety device, and a HMI with an easy user interface.

Have another question? Contact us

03-03-2025

A cobot palletizer or robotic palletizer is a cobot system that stacks goods and products onto a pallet. What are the benefits of a cobot palletizer? And where can they be used?

Read more25-05-2022

Global labor shortages continue to rise, also in the food (processing) industry. Automation is key, but where to start? End-of-line automation with cobots or robots can be the perfect first step. This blog gives 5 reasons why end-of-line automation is key.

Read more15-04-2025

In 2025, consumers continue to demand more and more from the bakery industry. It is time to consider how to improve the production process to meet these demands. Learn about the latest bakery trends and why bakery automation is key.

Read moreBoost Your End-of-Line Process with Automated PalletizingGet Started Today

To start, a cobot palletizing solution doesn’t take up much space like gantry or industrial palletizers, making it a cost-effective choice for businesses mindful of their footprint.

Smart Robotics offers a complete, one-stop-shop solution — from in-house developed software to integration with industry-leading hardware, and installation in less than a day at your facility.

With our online product editor, you can easily add new products and adjust box sizes directly from the cobot’s touchscreen without needing any technical skills.